Automate 2022

A Low-Code Approach to Industry 4.0

Teresa Martins, Neadvance Machine Vision

Throughout History, humankind has always been dependent on technology. People used the technology they had available to help make their lives easier and, at the same time, try to perfect it and bring it to the next level. This was (and still is) the very basic foundation of every industrial revolution.

- Details

- Download

- Quick View

- Only Available

If Logged In

Evolution of IoT Platforms in Multi-Site Operation

Michael Skurla, Radix IoT

The IoT acronym has given rise to a myriad of products flooding the market. The actual application and advantage of these technologies, however, has been a convoluted topic within all verticals. IoT devices offer abstract promises of data, but the reality is that much of the conversation on IoT has been on the wrong side of the equation.

- Details

- Download

- Quick View

- Only Available

If Logged In

Critical Initiatives in Artificial Intelligence

Michael Skocik, Advanced Robotics for Manufacturing Institute

Satyandra K Gupta, University of Southern California

Kel Guerin, READY Robotics

The Advanced Robotics for Manufacturing (ARM) Institute, the leading national consortium for Robotics and AI, has been working with its 300+ members to identify and prioritize initiatives that make AI/ML more accessible to U.S. Manufacturers.

- Details

- Download

- Quick View

- Only Available

If Logged In

A Multi-Robot System for Manufacturing

Glenn Saunders, Rensselaer MIC

In this session, we will discuss a multi-robot system that was developed in response to the COVID-19 pandemic. The pandemic brought to light a significant number of needs and shortcomings. Early on, one need that became readily apparent was that for Emergency Medical Facilities (EMF) that can be set up quickly to serve a variety of health care services, in a variety of settings such as urban and rural.

- Details

- Download

- Quick View

- Only Available

If Logged In

Designing Intelligent Robots for Air, Ground, Sea

YJ Lim, MathWork

- Details

- Download

- Quick View

- Only Available

If Logged In

Dynamic, Flexible Human-Robot Collaboration

Patrick Toner, Veo Robotics

Human-robot collaboration has become a major focus in manufacturing, with safety standards evolving accordingly. Speed and Separation Monitoring (SSM), as defined by ISO/TS 15066 and ISO 10218, is one of the modes of human-robot collaboration that allows robots to safely work near humans.

- Details

- Download

- Quick View

- Only Available

If Logged In

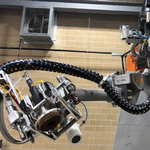

Robotic Inkjet Printing on 3D Surfaces

Branson Brockschmidt, Southwest Research Institute

Inkjet on 2-D surfaces has been a mature technology for many years, allowing for high-resolution deposition of fluid onto numerous materials, creating a thin but durable coating. Today, this technology is being expanded to 3-D surfaces via robotic systems. The robotic inkjet printing system is comprised of two main components: the printing system and the localization system.

- Details

- Download

- Quick View

- Only Available

If Logged In

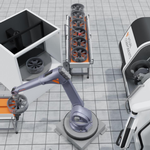

Collaborative Robots in Machine Tending

Cory Raizor, SCHUNK

Manufacturing leaders often struggle to take the first step in justifying investments in automation. The first robot is usually the most daunting in terms of unknowns for new users. Small to medium size businesses especially are taking advantage of Cobots and their intuitive nature to benefit from automation. For successful applications, deployments should be fast and straight forward with the ability to adapt to change quickly.

- Details

- Download

- Quick View

- Only Available

If Logged In

AI Systems for Flexible Industrial Automation

Pol Velasco, AUTIS

- Details

- Download

- Quick View

- Only Available

If Logged In

Robotic Paint Repair System

Marcus Pelletier, Robotics and Automation, 3M

- Details

- Download

- Quick View

- Only Available

If Logged In

How Thermal Imaging with IIoT

David Bursell, MoviTHERM

This presentation explains how industrial facilities are finding ways to mitigate and prevent fire damage by implementing infrared camera (IR) technologies and the Industrial Internet of Things (IIoT) for early fire detection.

Fire safety is an area that realizes the benefits of IIoT when combined with IR camera systems.

- Details

- Download

- Quick View

- Only Available

If Logged In

Capital Purchase, Leasing or Robotics-as-a Service

Misa Ilkhechi, Formic Technologies

This presentation will discuss the various options, including the different types of “as-a-service” models that can reduce the sticker shock – and risk - when it comes to automation.

- Details

- Download

- Quick View

- Only Available

If Logged In

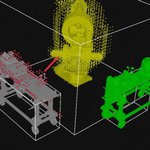

Value of 3D Simulation Software in Automation

Graham Wloch, Visual Components North America Inc.

3D Process Simulation software is becoming an integral aspect of automation planning, validation of robot integration, the interaction between human capital and automation, and Digital Twin (or virtual commissioning). We will illustrate the value of simulation software at the beginning stages of automation planning, enabling engineers (process, industrial and manufacturing), and plant costing analysts.

- Details

- Download

- Quick View

- Only Available

If Logged In

De-Risk Your Supply Chain with Smart Manufacturing

Joanne Moretti, Fictiv

Supply chain risks have become overwhelming, with the pandemic and its after effects proving that traditional supply chain strategies and manufacturing ecosystems are ill-equipped and unlikely to survive. That is why 91% of executive respondents to the 2021 State of Manufacturing survey said they have increased investment in digital transformation over the prior year as the lynchpin of a smart manufacturing strategy.

- Details

- Download

- Quick View

- Only Available

If Logged In

Natural Language Commands for Robots

Rogerio Bonatti, Microsoft

Natural language is the most intuitive medium for us to interact with other people when expressing commands and instructions. However, using language is seldom an easy task when humans need to express their intent towards robots, since most of the current human-machine interfaces require rigid templates with a static set of action targets and commands.

- Details

- Download

- Quick View

- Only Available

If Logged In

Modern DevOps Practices with Industrial Automation

Adam Gluck, Copia Automation

DevOps tools have transformed how business software is built, but there were barriers in introducing the same toolsets to industrial automation due to the unique nature of PLC programming. Recently, however, companies are starting to embrace Git-based source control to manage their automation projects. Git-based source control enables greater collaboration between teams, suppliers, and customers.

- Details

- Download

- Quick View

- Only Available

If Logged In

Perception-driven Adaptation

Xiyang Yeh, Flexiv Robotics Inc

To meet the demands for increasingly flexible automation environments in manufacturing, healthcare, and agriculture, robots need to truly perceive the environments and utilize the gathered information to synthesize complex intelligent behaviors and reactively adapt to uncertainties during execution. Over the years, there has been significant development in the fields of robotics and machine learning in this direction.

- Details

- Download

- Quick View

- Only Available

If Logged In

Industrial Metaverse & Mixed Reality

Rajat Gupta, Microsoft

The presentation will focus on two aspects of Mixed Reality in the Enterprise -

1. How Mixed Reality (Augmented Reality and Virtual Reality) is being adopted in the enterprise?

2. How Mixed Reality and Metaverse are different?

- Details

- Download

- Quick View

- Only Available

If Logged In

Human + Machine = Operational Excellence

Prasad Akella, Drishti

Jeffrey Liker, Drishti

From pandemics and global warming to changing market dynamics, myriad challenges mean companies need to be ready to alter production at a moment's notice. Manufacturers agree that humans are more adaptable than automation, but human workers present variability. Manufacturers can gain adaptability while error-proofing their workers using AI and video analytics.

- Details

- Download

- Quick View

- Only Available

If Logged In

Extending Cobot Applications

Rick Conneely, Eaton Tripp Lite

Collaborative robots are being applied in exciting new applications everyday given their ease of use and ability to connect to any 120V power source. Much of the focus today is on the end effectors and their ability to complement the collaborative work with employees. The power requirements to run cobots are typically considered a given and often pushed to the person deploying or running the cobot.

- Details

- Download

- Quick View

- Only Available

If Logged In

Top 10 Questions to Ask a Cobot Supplier

Sumer Petrous, Universal Robots

Collaborative robots make up the fastest-growing segment of the robotics industry, thanks to their affordability and fast deployment compared to traditional robots. But not all manufacturing processes have the same outlook for cobot automation, and not all cobot suppliers are created equal. Johnny Leak, Channel Development Manager at Universal Robots, will explore the unique technologies in collaborative robots that are openin

- Details

- Download

- Quick View

- Only Available

If Logged In

Making Collaborative Applications Collaborative

Greg Buell, FANUC America

Whether working hand in hand with your robot, or rarely interacting with it, understanding what actually makes a collaborative application collaborative is important and will go a long way to choosing the right solution to your automation challenge. This presentation will discuss 2 distinctly different collaborative applications and what it is that really makes them collaborative.

- Details

- Download

- Quick View

- Only Available

If Logged In

Cobots & Welding

Stu Shepherd, Universal Robots

Cobot welding has seen an explosion in interest over the last few years, thanks to the improved productivity they offer metal fab businesses and the improved work they offer skilled welders. Join Stu Shepherd, Vertical Director at Universal Robots, to discover how cobot users are attracting and retaining talent, securing more work, and expanding productivity with their collaborative welding systems.

- Details

- Download

- Quick View

- Only Available

If Logged In

Save Time and Money with Cobot Deployment

Étienne Samson, Robotiq

- Details

- Download

- Quick View

- Only Available

If Logged In

Automotive Glass Priming with Collaborative Robots

Johnny Rodriguez, Pilz Automation Safety

Jordan Punch, Pilz Automation Safety

Automotive glass is secured to the car body using adhesive to secure and seal the glass while adding to the structural strength of the vehicle. The glass must be prepared by a two-step process of cleaning and priming the glass.

- Details

- Download

- Quick View

- Only Available

If Logged In

Evolving Applications for Collaborative Robots

Chris Caldwell, Yaskawa America, Inc.

As robots are increasingly deployed to supplement our workforce in new applications, collaborative robots are becoming the gateway to automation. One study on the advance of automation found “over 88% of organizations believe that automation will accelerate human achievement and be most effective when it complements humans” (UiPath et al, 2019).

- Details

- Download

- Quick View

- Only Available

If Logged In

Advances in Motors

Todd Brewster, Kollmorgen

The drive toward higher efficiency in manufacturing has been focused over the years on higher power motors applications used in heavy industries. The design considerations for permanent magnet (PM) motors used in robotics applications offer considerable differences compared to constant speed efficiency gains.

- Details

- Download

- Quick View

- Only Available

If Logged In

Robot Interoperability in the Industry 5.0 World

Pat Duda, KUKA Robotics

The advent of machine learning, AI, and Big Data promises to assist manufacturing workers to achieve new levels of efficiency. Applying these technologies to your processes requires reaching beyond the capabilities of software and hardware of robots and their controllers. Taking advantage of the best technologies often requires many of the capabilities to be offloaded to specialized hardware or the cloud.

- Details

- Download

- Quick View

- Only Available

If Logged In

Designing Your Automation with Smart Conveyance

Ben Hope, SuperTrak CONVEYANCE

- Details

- Download

- Quick View

- Only Available

If Logged In

Improving High-Precision Motion System Performance

Jason Goerges, ACS Motion Control

- Details

- Download

- Quick View

- Only Available

If Logged In

Advanced EOAT Applications and Tool Changers

Bethany Colbry, ATI Industrial Automation

The most common application for the robotic tool changer has historically been material handling. As robots are used for more applications we see an increase in complexity of the end-of-arm tooling (EOAT). Applications featuring multiple joining tools, vision, and advanced motion control are becoming more common.

- Details

- Download

- Quick View

- Only Available

If Logged In

Mobile Artificial Intelligence Vision System

Walter LaPlante, Ford Motor Company

Mobile Artificial Intelligence Vision System (MAIVS) uses computer vision and machine learning for real-time defect detection, where it can quickly notify operators that defects are apparent and action is needed to ensure zero defect forward. The system consists of an iOS edge device running the IBM Maximo Visual Inspection Mobile application.

- Details

- Download

- Quick View

- Only Available

If Logged In

Deploying Open-Source on the Shop Floor

Matthew Robinson, Southwest Research Institute

The ROS-Industrial open source project has been around now for nearly 10 years. There have now been extensive examples of ROS and other open source tools running in factories.

- Details

- Download

- Quick View

- Only Available

If Logged In

Collaborative Palletizing Applications

Kristian Hulgard, OnRobot

- Details

- Download

- Quick View

- Only Available

If Logged In

From No-Bot to Robot

Jeff Huerta, Vecna Robotics

- Details

- Download

- Quick View

- Only Available

If Logged In

What’s The True Cost of Robotic Palletizing?

Étienne Samson, Robotiq

- Details

- Download

- Quick View

- Only Available

If Logged In

Human-Robot Collaboration

Lior Elazary, inVia Robotics

- Details

- Download

- Quick View

- Only Available

If Logged In

Workforce Development and Accelerated Automation

Craig Salvalaggio, Dematic

Technological advances in industrial automation mean robots can take on dull, dirty, and dangerous tasks - elevating human workers to higher-value positions. But what are companies doing to get ready? How can companies skill, train and retain workers in this new paradigm of warehouse automation?

- Details

- Download

- Quick View

- Only Available

If Logged In

Getting Started with Robots as a Service (RaaS)

Mandy Dwight, RIOS Corporation

Clinton Smith, RIOS Corporation

A new breed of quick deploying, cost efficient robotic workcells are available to automate dexterous and labor-intensive tasks such as end of line packaging, order fulfillment, food handling, assembly, machine tending, or inspection in a “pay as you go'' Robotics as a Service (RaaS) pricing model.

- Details

- Download

- Quick View

- Only Available

If Logged In

Manufacturing Consideration in Today's New Normal

Scott Marsic, Epson Robots

We will explore the "how" and "why" of automation from the vantage point of today's decision makers as they evaluate robotics and manufacturing within their business. Topics will include changes to customer pain points, onshoring & near-shoring impacts, market trends and top insights for project success.

- Details

- Download

- Quick View

- Only Available

If Logged In

How AI is Transforming Manufacturing and Logistics

Amit Goel, NVIDIA

Everything will become smarter in the factory floor, from machines to handlers and from ground vehicles to conveyor belts. Edge AI and Robotics are playing a vital role to transform industrial automation processes to fully autonomous systems in manufacturing and logistics. Adding intelligence at the edge enables machines in production to sense the environment, act autonomously and make critical decisions.

- Details

- Download

- Quick View

- Only Available

If Logged In

Ethics and Bias in AI - Understanding the Risks

Tom Knauer, Balluff

- Details

- Download

- Quick View

- Only Available

If Logged In

Condition Monitoring And Predictive Maintenance

Tom Knauer, Balluff

- Details

- Download

- Quick View

- Only Available

If Logged In

Using Simulation to Maximize Efficiency for Robots

Anthony Navarro, Unity

Simulation is a powerful tool in robotics system development allowing you to design a system that performs in diverse environments, adapts to changes, and operates safely, saving both time and money. This talk will cover the advantages of using simulation in robotic systems development and deployment and explore strategies used in simulation that enable robust and efficient systems.

- Details

- Download

- Quick View

- Only Available

If Logged In

Scaling Your Logistics Robotic Solution

Matt Wicks, Celestica

There is no shortage of excitement in the logistics space today – pandemic-driven e-commerce and consumer expectations for same-day delivery, increased by online and curbside pick-up service options as well as the rise of urbanization, and escalating labor challenges. It’s no wonder companies are turning to robotics to help solve these challenges.

- Details

- Download

- Quick View

- Only Available

If Logged In

Simulated Environments for the Future of Autonomy

Max Versace, Neurala

- Details

- Download

- Quick View

- Only Available

If Logged In

Cybersecurity: Secure Digital Transformation

Leah Dodson, Jeremy Dodson, and Jay Korpi (NextLink Labs)

Today’s cybersecurity landscape has organizations across the globe on edge. The rise of organized cybercrime has provided attackers more resources than ever before, resulting in critical vulnerabilities being identified and exploited almost daily. How can your organization support modern growth and digital transformation while protecting the security and safety of your assets?

- Details

- Download

- Quick View

- Only Available

If Logged In

AI in Manufacturing: The Truth and the Myth

Juan Aparicio, Rapid Robotics

There is significant hype around AI and its potential applications in manufacturing. In this session, join A3's AI Technology Strategy Board member - Juan Aparicio - in discovering the common misconceptions and myths of AI in manufacturing.

- Details

- Download

- Quick View

- Only Available

If Logged In

Mobility & Manipulation in the Warehouse

Nicolas De Keijser, Boston Dynamics

Brian Gaunt, DHL Supply Chain

Truly flexible solutions for warehouse automation require advanced manipulation and mobility. This session will focus on how crucial robotic manipulation is to the careful handling of carton boxes and cases, and how robotic movement untethered by power lines or bolted-down infrastructure can make way for additional automated tasks in the warehouse.

- Details

- Download

- Quick View

- Only Available

If Logged In

Intro to Mobile Robot Risk Assessment

Bob Bollinger, Dynamic Horizons Automation Solutions

- Details

- Download

- Quick View

- Only Available

If Logged In

Progress Toward Multi-application Indoor AMRs

Pablo Molina, Avidbots

Most indoor autonomous mobile robots (AMRs) on the market today are specialized, often addressing a single application/service and market segment. Today’s robots solve for a limited use case, deliver rather narrow benefits, and, as a result, offer little potential to grow given the limited market that they solve.

- Details

- Download

- Quick View

- Only Available

If Logged In

Integrators Insights on AMR Integration

Terry Meister, AMT

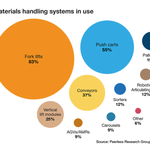

Autonomous Mobile Robots are being used anywhere from pallet relocation to implementing a robot on top of the AMR for use in production facilities. Alone or with an attached tool, AMRs are assisting plants worldwide. You will even see automated forklifts that fall under the AMR umbrella.

- Details

- Download

- Quick View

- Only Available

If Logged In

Using Fleet Analytics for Continuous Optimization

Adrian Ennis, OTTO Motors

Material handling is the lifeblood of modern manufacturing and warehousing. Proper flow of material into, out of, and within facilities is what makes businesses successful. Automating material handling with AMRs improves reliability to provide business continuity and increases throughput to maximize profit.

- Details

- Download

- Quick View

- Only Available

If Logged In

AMRs and Order Picking Automation

Yaqing Sun, Omron Automation Americas

In this presentation, we will share a few specific case studies of using AMRs for order picking assistance in conventional warehouses.

- Details

- Download

- Quick View

- Only Available

If Logged In

Reducing Risks Associated with Whole Body Access

Aaron Woytcke, SICK Inc.

The concept of “whole body access” – as well as the associated r+AA39isks to employees – is by no means new to industry; in fact, it is an enduring risk prevalent in many automated systems in factory and logistics automation.

- Details

- Download

- Quick View

- Only Available

If Logged In

Picking Transparent Objects from a Random Bin

Sina Afrooze, Apera AI

This course covers 2D & 3D machine vision camera calibration for machine guidance including for industrial robots together with basic information on the types of industrial robots in use today.

- Details

- Download

- Quick View

- Only Available

If Logged In

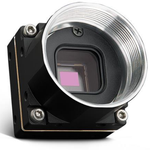

AI Systems for Flexible Industrial Automation

Michael Suppa, Roboception GmbH

This course covers 2D & 3D machine vision camera calibration for machine guidance including for industrial robots together with basic information on the types of industrial robots in use today.

- Details

- Download

- Quick View

- Only Available

If Logged In

Flexible Robot Grasping of Unknown Objects

Jose Luis Susa Rincon, Siemens

- Details

- Download

- Quick View

- Only Available

If Logged In

The Main Source of Error in Vision-Guided Robots

Jesse Masters, Zivid

This course covers 2D & 3D machine vision camera calibration for machine guidance including for industrial robots together with basic information on the types of industrial robots in use today.

- Details

- Download

- Quick View

- Only Available

If Logged In

Vision Guided Robotic Bin Picking

David Bruce, FANUC America Corporation

This course covers 2D & 3D machine vision camera calibration for machine guidance including for industrial robots together with basic information on the types of industrial robots in use today.

- Details

- Download

- Quick View

- Only Available

If Logged In

Introduction to Robot Risk Assessment

Jeff Fryman, Association for Advancing Automation

- Details

- Download

- Quick View

- Only Available

If Logged In

Automating Visual Inspection

Caleb Davis, UnitX

Of all the places where artificial intelligence is making a difference in manufacturing, vision inspection use-cases may be the most significant and most mature. Join these industry experts as they discuss how AI-based vision applications are leading higher quality, enhanced processes and greater flexibility.

- Details

- Download

- Quick View

- Only Available

If Logged In

Vision AI Improving Factory Floor Inspection

Steve Walsh, Neurala

Of all the places where artificial intelligence is making a difference in manufacturing, vision inspection use-cases may be the most significant and most mature. Join these industry experts as they discuss how AI-based vision applications are leading higher quality, enhanced processes and greater flexibility.

- Details

- Download

- Quick View

- Only Available

If Logged In

Event-based Vision and Machine Vision Applications

Davide Migliore, Prophesee

Of all the places where artificial intelligence is making a difference in manufacturing, vision inspection use-cases may be the most significant and most mature. Join these industry experts as they discuss how AI-based vision applications are leading higher quality, enhanced processes and greater flexibility.

- Details

- Download

- Quick View

- Only Available

If Logged In

Solving Visual Inspection Errors with AI

Ed Goffin, Pleora Technologies

Of all the places where artificial intelligence is making a difference in manufacturing, vision inspection use-cases may be the most significant and most mature. Join these industry experts as they discuss how AI-based vision applications are leading higher quality, enhanced processes and greater flexibility.

- Details

- Download

- Quick View

- Only Available

If Logged In

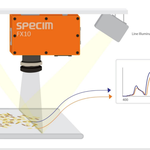

Hyperspectral Vision Applications

Mathieu Marmion, SPECIM

Hyperspectral imaging has been available for decades, but faster and cheaper available sensors make the method now attractive for the industry. In fact, hyperspectral imaging combines imaging and spectroscopy, offering new insights over traditional systems, mostly based on Xrays, RGB or multispectral sensors. This presentation will focus on the advantages the hyperspectral technology with success integration success stories.

- Details

- Download

- Quick View

- Only Available

If Logged In

Crash Course in Automation Sensors & Cables

Will Healy III, Balluff Worldwide

Never implemented automation before? New grad, new job, new expectations? No technical experience? No Problem! In this crash course, we will cover how a machine works and the basics of automation electrical systems. Plus, we will review a few of the most common sensor technologies.

- Details

- Download

- Quick View

- Only Available

If Logged In

Leveraging Multiple EOAT Handling Technologies

Tom Reek, SCHUNK

Engineers and production managers are looking to maximize their investments in automation, being able to deploy and redeploy robots for multiple and changing tasks. Even within similar manufacturing processes, workpieces may continually change in size, shape, weight, and materials creating the need for adaptable robot EOATs.

- Details

- Download

- Quick View

- Only Available

If Logged In

The Great Resignation and Automation

Lou Finazzo, FANUC America

Robots and automation are easier to use than ever before - they are more flexible, reliable and affordable. Those benefits alone are all reasons to do a 360 on traditional production methods, but add the ‘Great Resignation’ to the mix and you’re looking at multiple challenges.

- Details

- Download

- Quick View

- Only Available

If Logged In

Robots-as-a-Service (RaaS)

Fouad Khalil, Locus Robotics

Safely deploying robotics in the warehouse requires overcoming numerous complex technical and operational challenges, including security and compliance. Like other Internet of Things (IoT) devices, robotics can be vulnerable to a variety of cyberattacks, exploiting physical and digital interfaces.

- Details

- Download

- Quick View

- Only Available

If Logged In

Robotics and AI Governance

Dominik Boesl, Micropsi Industries

Trust is the key to safe, successful automation. But how do we build trust when AI and machine learning systems have the ability to adapt and evolve. Join these industry experts in a discussion on trust and explainability in autonomous systems.

- Details

- Download

- Quick View

- Only Available

If Logged In

Ethics and Bias in AI - Understanding the Risks

Corey Ryan, KUKA

Trust is the key to safe, successful automation. But how do we build trust when AI and machine learning systems have the ability to adapt and evolve. Join these industry experts in a discussion on trust and explainability in autonomous systems.

- Details

- Download

- Quick View

- Only Available

If Logged In

The Key to Building Trust in Autonomous Systems

Nathan Bivens, FORT Robotics

Trust is the key to safe, successful automation. But how do we build trust when AI and machine learning systems have the ability to adapt and evolve. Join these industry experts in a discussion on trust and explainability in autonomous systems.

- Details

- Download

- Quick View

- Only Available

If Logged In

Building an AI or Smart Manufacturing Strategy

Christine Boles, Intel

Manufacturers are always seeking new ways to optimize their operations and reduce costs. Now, as sustainability continues to become top of mind for many organizations, it can seem like a competing objective. However, it’s possible to achieve both business and sustainability goals by adopting a data-driven strategy to fuel AI and machine learning applications. Today, most factories still only leverage a fraction of their operational da

- Details

- Download

- Quick View

- Only Available

If Logged In

Intent Prediction in Human Robot Interactions

Paul Santi, FANUC America

Sara Masoud, Wayne State University

Intent prediction, also known as intention recognition or detection, is one of the core components of social cognition. From the age of 18 months, human beings have been shown to be able to extrapolate intentions from observed actions. A key technical component for intent prediction from observed bodily movements is the discovery and utilization of the spatiotemporal patterns behind those movements.

- Details

- Download

- Quick View

- Only Available

If Logged In

Deep Learning and Vision AI with Manufacturing

Max Versace, Neurala

The manufacturing world is facing old and new challenges. Companies are facing irregular patterns in consumer demands and increased pressures on machine utilization, production efficiencies, and quality control – and they need to address all of this with fewer people on the factory floor.

- Details

- Download

- Quick View

- Only Available

If Logged In

Industrial Edge - Make the Most of Your Data

Chris Liu, Siemens

The volume of data in industry continues to grow. How can you acquire knowledge from this vast amount of information so you can make the right decisions and take fast action? Industrial Edge is an integral part ofthe Digital Enterprise portfolio that serves to transform endless volumes of data into limitless opportunities. Join us for more information including an overview of architecture, benefits,use cases, and where to start.

- Details

- Download

- Quick View

- Only Available

If Logged In

Where Should You Begin With Industry 4.0 and IIoT

Christina Pierce, Panasonic IIoT Solutions

Though the manufacturing industry generally accepts the need to automate, the barrier to entry can cause hesitation. However, there are clear baby steps manufacturers can take to begin their journey to automation. In this session, we’ll look at several initial steps in the manufacturing process that can be improved with IIoT, including paper-based operations, improving material flow, and locating inventory.

- Details

- Download

- Quick View

- Only Available

If Logged In

The Multi-Robot Warehouse of the Future

Florian Pestoni, InOrbit

While robot deployments within warehouses and fulfillment centers tend to focus on a single robot platform (either mobile or fixed robot arm), the day is coming when multiple robot types will be traversing the floor. Cleaning robots, inventory robots, and drones will soon be working alongside delivery robots and autonomous forklifts to get their tasks done.

- Details

- Download

- Quick View

- Only Available

If Logged In

AMRs and the Human Workforce

Todd Graves, Seegrid

Manufacturing, e-commerce, and logistics facilities are struggling to fill surging order volumes on time and accurately with today’s evolving demands, especially amid an ongoing labor shortage. To solve for today’s biggest challenges, more companies are turning to automation solutions to increase reliability, safety, and productivity for the competitive advantage. But what does this mean for the future of the human workforce?

- Details

- Download

- Quick View

- Only Available

If Logged In

Using Robotics Business Intelligence to Optimize P

Jason Walker, Locus Robotics

Business intelligence is transforming all sectors of the economy, including t warehousing and manufacturing. As robotic automation becomes an integral part of these operations, effective use of the data these solutions generate gives critical visibility into what’s going on inside your facility, and provides a valuable and actionable resource for planning, operations, labor management and more.

- Details

- Download

- Quick View

- Only Available

If Logged In

Mobile Robot Application Considerations

Denise Ebenhoech, KUKA Robotics

In recent years, advances in technology have broken traditional AGVs from their tethered paths and given way to a new generation of sophisticated mobile platforms that can independently support more intricate processes and overcome past time and space limitations.

- Details

- Download

- Quick View

- Only Available

If Logged In

Top 5 Trends in the AMR Market

Søren E. Nielsen, Mobile Industrial Robots A/S

Søren E. Nielsen, the president of Mobile Industrial Robots (MiR), the leading manufacturer of collaborative and autonomous mobile robots, discusses the current forces driving the AMR market.

- Details

- Download

- Quick View

- Only Available

If Logged In

AI-Driven AI Fleet Management

Andreas Boedenauer, AGILOX North America, Inc.

Business success depends on a lot of factors: Innovative products, outstanding services, financial prudence, manufacturing excellence. To excel, all parts of the organization work together in sync. Consequently, mitigating the risk for any disruption of this collaboration is a key objective of management. In a worst case scenario, a Single Point Of Failure can bring the entire operation to a costly halt.

- Details

- Download

- Quick View

- Only Available

If Logged In

Intelligent Robotics for the Modern Warehouse

Brandon Coats, Mujin

Logistics facilities have a need for more intelligent robotic systems, which are value-adding, production-ready, and reduce the cost of the overall material handling solution. The next generation of robots should be capable of perception, awareness, and autonomous decision-making, which will allow companies to deploy more robotic systems into production and into new, more advanced applications.

- Details

- Download

- Quick View

- Only Available

If Logged In

Automate Your Visual Weld Inspection

Jeffrey Noruk, Servo Robot Corp

- Details

- Download

- Quick View

- Only Available

If Logged In

Ensuring Success with EV Powertrain Deployments

Vikram Mankar, GE Digital

GE Digital Smart Factory MES is designed for rapid multi-plant deployments. Build first template site, export the configuration, import into subsequent sites changing site relevant master data). The Smart Factory MES user interface has a mobile first HTML5 UI and can be Dockerized to ensure 100% uptime.

- Details

- Download

- Quick View

- Only Available

If Logged In

Understanding Robot Accuracy

Houssaine Waled, KUKA Robotics

Many robotic applications require high positional and path accuracy. These include machining, non-destructive testing, and any application that uses offline programming. Robots have come a long way in terms of static and dynamic performances. However, failing to understand robot accuracy and the factors that affect it can lead to undesirable outcomes. Many users have high expectations when it comes to robot accuracy.

- Details

- Download

- Quick View

- Only Available

If Logged In

Maximize Technology and Investment

Jim Witherspoon, Zebra Technologies

Artificial intelligence and deep learning solutions are the next generation of vision inspection. From a barcode reader to a deep learning solution, this presentation will share how companies are solving problems today and future-proofing and enhancing their solutions for tomorrow.

- Details

- Download

- Quick View

- Only Available

If Logged In

3D Printed End-of-Arm Tools

Liz Stortstrom, HP 3D Printing

The use of additive manufacturing in the robotics and industrial automation industry is becoming more prevalent every day. Material handling solutions are highly customized to the end-user, and additive manufacturing can complement and address many of the shortcomings of traditional manufacturing methods like machining and injection molding.

- Details

- Download

- Quick View

- Only Available

If Logged In

Vision Automation Headwinds and Tailwinds

Dave Kelly, Perceptron

The adoption of vision-enabled automation within the manufacturing sector has been accelerating, driven by widening demand and new 3D vision technology. The demands for quality, throughput, speed, agility, lower costs, and recently labor shortages are being met by ever more automation, particularly vision-enabled automation.

- Details

- Download

- Quick View

- Only Available

If Logged In

Connecting Automation to Business Challenges

Bryan Bird, Universal Robots

Bryan Bird, Regional President of US/Canada for Universal Robots, is building the case for manufacturers getting ahead of their most pressing business challenges with collaborative robots. This presentation will provide an overview of common manufacturing challenges and demonstrate how collaborative automation systems bring performance improvements to directly address these challenges.

- Details

- Download

- Quick View

- Only Available

If Logged In

Lessons from the Field

Jim Lawton, Zebra Technologies

Is there a way to ensure that investment in automation can deliver all that is expected? For many companies, betting on automation is not a decision made lightly. Of course, there’s the pure cost of the solution, but all too often there are unknowns that quickly add up – and eat up any potential ROI. Things like the need to reconfigure space or workflows. Often, there is intensive training and additional equipment.

- Details

- Download

- Quick View

- Only Available

If Logged In

Getting Started in Robotics: Pt 2

Bob Bollinger, Dynamic Horizons Automation Solutions

Industrial Robots are the heart of Lean Manufacturing and are vital to the current vibrant manufacturing economy in North America. The “Getting Started with Robotics” presentation is an introduction to the Industrial Robotics or Flexible Automation Industry.

- Details

- Download

- Quick View

- Only Available

If Logged In

Getting Started in Robotics: Pt 1

Bob Rochelle, Güdel

Industrial Robots are the heart of Lean Manufacturing and are vital to the current vibrant manufacturing economy in North America. The “Getting Started with Robotics” presentation is an introduction to the Industrial Robotics or Flexible Automation Industry.

- Details

- Download

- Quick View

- Only Available

If Logged In

*Assets marked for members only are subject to membership level eligibility.

- Platinum

- Gold

- Silver

- Bronze

- Non-Member